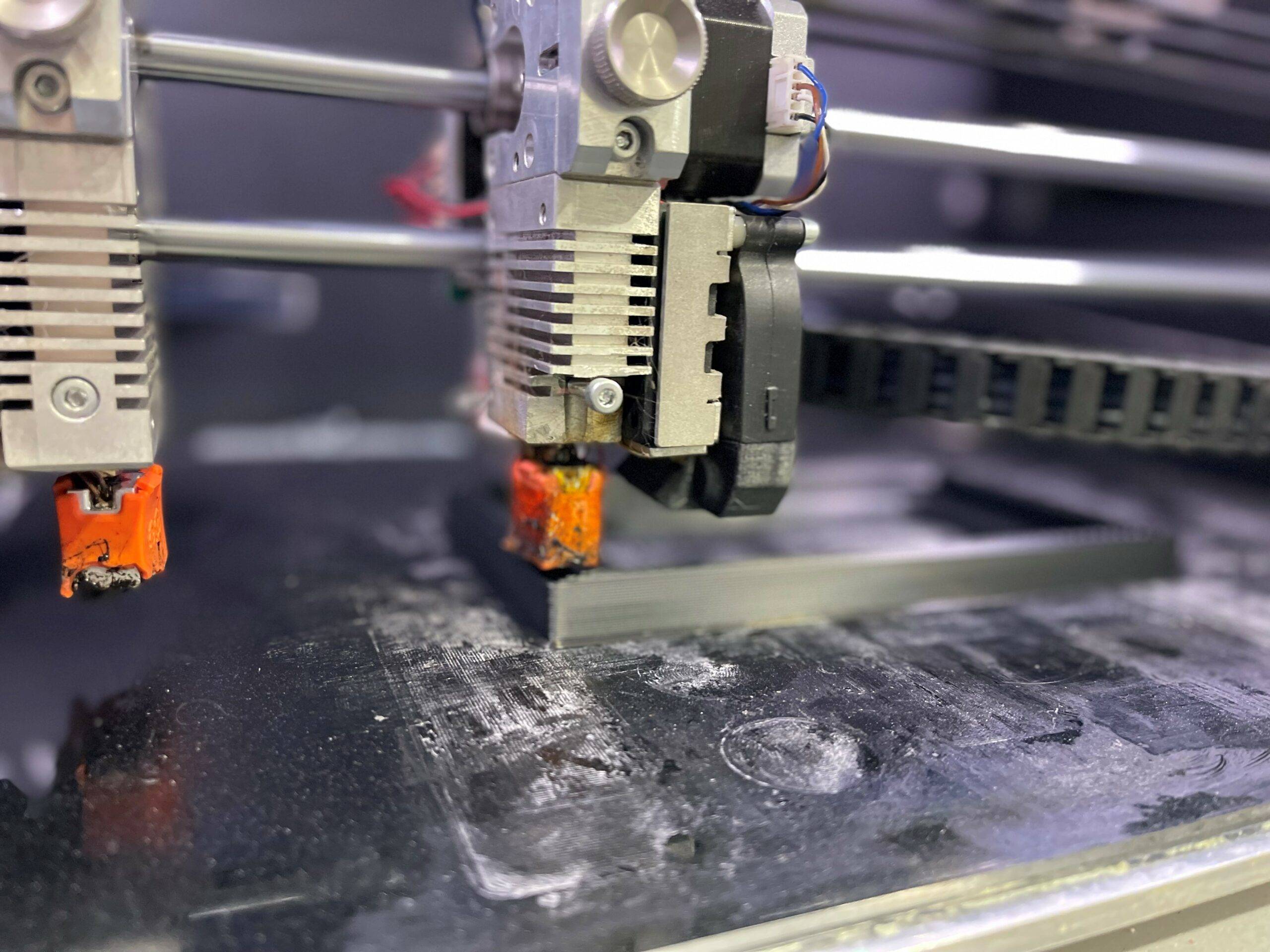

3D Printing Service

Print smooth strong parts using abs like resin. Suitable for small batch production and precise parts.

HIPS (High Impact Polystyrene)

PVA (Polyvinyl Alcohol)

ABS Like, Standard, Flexible

PETG, PLA, PLA+, TPU, ABS, CF ABS, CF Nylon, CF PETG

115mm x 65mm x 155mm

330 x 320 x 205mm

Uses

Design inspection, prototyping, proof of concept, & functional parts

We use our price calculator to send you an online quote, upload your 3D file to receive your quote.

How much does it cost to get a 3D print? Several factors can affect prices, but the main ones are, how large the object is, what material you chose and whether you need multiples or a one-off 3D print?

3 ways to reduce costs.

Use less material by optimizing the design and reducing infill density.

Print at a lower resolution to reduce printing time and material usage.

Use a lower-cost material, such as PLA, while considering the material’s properties for suitability.

We are ready to help. If you have an idea, a product you want to bring to life, design verification or maybe files that need repairing. Perhaps you have STEP files or an unsupported format, let us convert them for you.

Additive manufacturing is a fascinating process that uses a variety of technologies and materials to create three-dimensional objects from digital files. But it’s not just about the technology and materials; it’s about choosing the right combination to suit your project’s needs.

When it comes to additive manufacturing, choosing the right material is crucial. The decision will depend on many factors, such as the end-use of the product, the required strength, and functionality. Are you looking to create a part for outdoor use, or is the feel of the product more important? These are just a few of the considerations that must be considered before settling on the material for your project.

Moreover, the number of parts required is also a critical factor to consider. The quantity may affect the most efficient manufacturing process, with some materials or technologies being better suited to mass production than others.

So before you embark on your additive manufacturing project, be sure to take into account the various factors at play and Give Us a Call. We can ensure that you choose the best material and technology for your specific needs.

Additive manufacturing involves various technologies and materials to manufacture 3D parts from digital files. Choosing the appropriate material for your project depends on numerous factors, especially its intended use.

Important factors to consider when selecting the right material include:

By thoughtfully evaluating these factors, you can select the best material for your project or parts, leading to a successful outcome.